The Ti Tree bioreactor is designed to rapidly stablise waste, generate green energy through efficient biogas production and enhance waste settlement through management of the waste’s natural microbial decomposition.

The bioreactor provides a favourable environment for the microbial decomposition process – known as anaerobic digestion – to occur. This process requires that waste reach its optimum moisture content followed by a decrease in the oxygen content.

This is achieved through precise management of the moisture balance within the system. Waste typically consists of 10-30% moisture, which is well below the optimum level (being 40-45%) required for active biological decomposition.

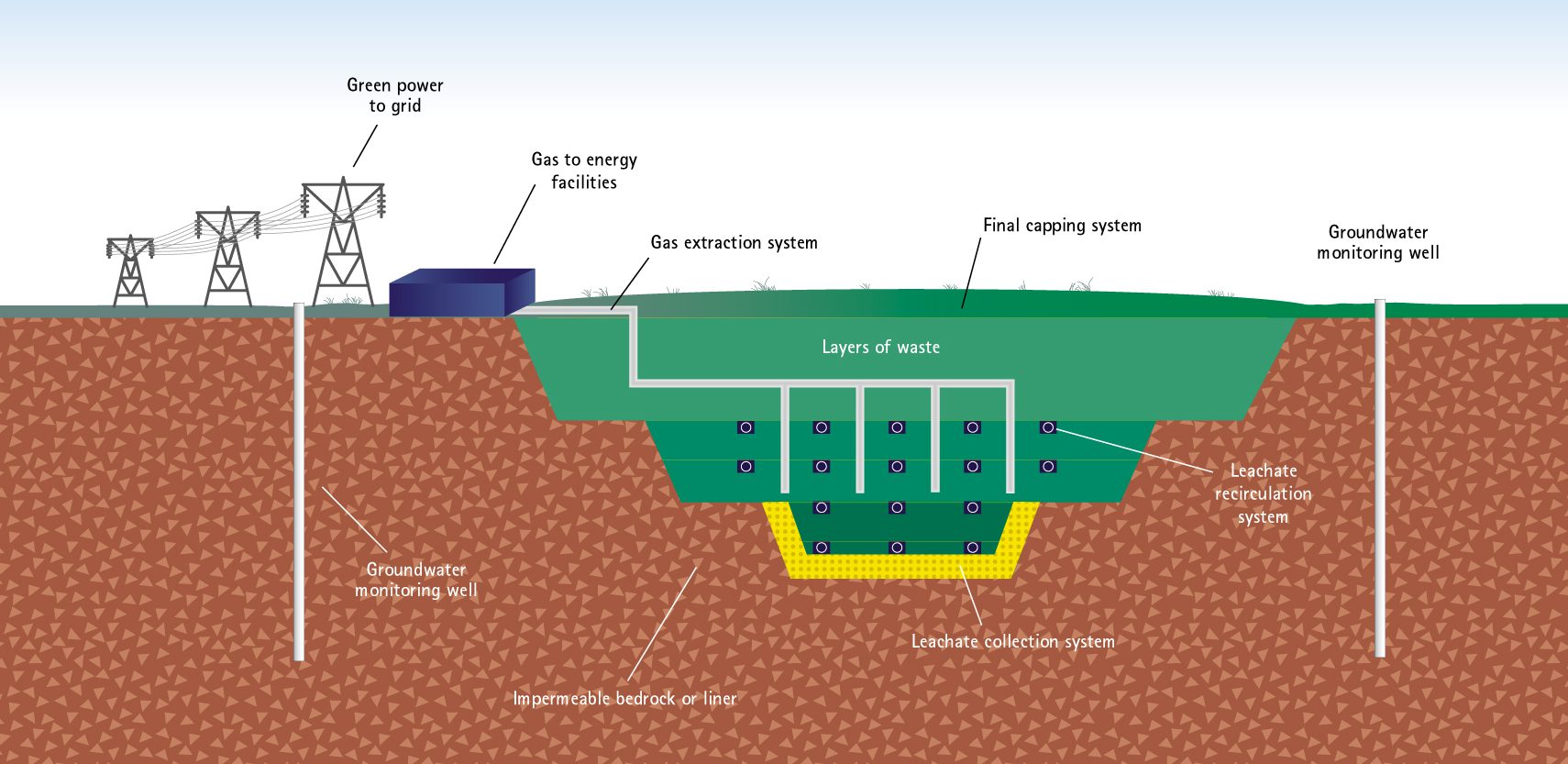

The bioreactor maintains optimum moisture levels by recirculating leachate (nutrient rich water produced by decomposing waste) and other liquids, such as stormwater and biological organic liquids, through an extensive network of pipes. This ensures optimal decomposition conditions and increases the effciency of the bioreactor.

Other enhancement methods can include microbial inoculation, waste shredding, pH adjustment, pre-disposal and post-disposal conditioning and temperature management.

Combined with water management, these practices can expedite waste degradation/stabilisation and increase early biogas production to utilise as a green energy source.